We use cookies to enhance your experience. By continuing to browse this site you agree to our use of cookies. More info.

A catalytic converter is a vehicle emissions control device that is used to convert toxic byproducts of combustion (occurring in the exhaust of an internal combustion engine) to less toxic substances by performing catalyzed chemical reactions. The reactions tend to vary depending on the type of catalyst installed. What materials are used in catalytic converters? Dpf Suppliers

Image Credit: Setta Sornnoi/Shutterstock.com

This vehicle emission control device was invented by Eugene Houdry, a French mechanical engineer involved with catalytic oil refining. In 1973, former General Motors President Robert Stempel decided to begin their implementation in automobiles.

Since then, many scientists have been working on the development of the catalytic converter and as of 2010, they are mandatory on all cars in the US.

Although these devices are primarily used in exhaust systems in automobiles, they are also modified and used on trucks, buses, forklifts, mining equipment, generator sets, locomotives, motorcycles, airplanes, and other engine-fitted devices. They are also used on some wood stoves to control emissions.

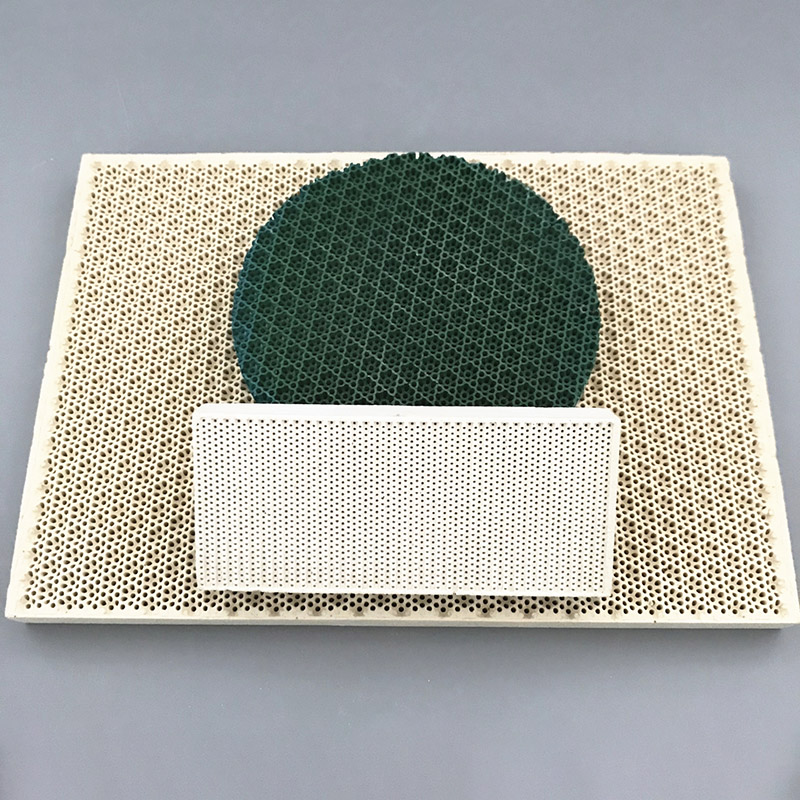

The catalytic converter is made up of several materials. The catalyst core or substrate varies according to the vehicle. For example, when these devices are used in automobiles, the core is usually a ceramic monolith with a honeycomb structure.

When manufactured in large quantities, ceramic cores can be inexpensive. Metallic foil monoliths are made of an iron-chromium-aluminum combination and are used in some applications. Metallic cores are less expensive when manufactured for use in small production runs, such as in sportscars in which low back pressure and reliability under constant high load are essential. Both these materials are designed to provide a high surface area to support the catalyst washcoat.

The catalyst washcoat is a carrier for the catalytic converter materials, which is used to disperse the materials over a high surface area. Titanium dioxide, aluminum oxide, silicon dioxide, or a combination of silica and alumina can be used. The catalytic materials are suspended in the washcoat before application to the core. Washcoat materials have rough, irregular surfaces to increase surface area, which helps to maximize the catalytically active surface available to react with the engine exhaust.

The catalyst used in the converter is mostly a precious metal such as platinum, palladium, and rhodium. Platinum is used as a reduction catalyst and as an oxidation catalyst. Although platinum is a very active catalyst and widely used, it is very expensive and not suitable for all applications. Rhodium is used as a reduction catalyst, while palladium is used as an oxidation catalyst.

In some cases, cerium, iron, manganese, and nickel are also used. However, some companies forbid the use of some of these.

The key types of catalytic converters are listed below with a brief introduction:

The catalytic converter was specifically invented to decrease harmful pollution caused by gases produced from the combustion of hydrocarbon-based fossil fuels in cars. Studies reveal that these devices can decrease hydrocarbon emissions by about almost 87%, carbon monoxide by 85%, and nitrous oxide by 62% during the expected life of a vehicle.

More from AZoM: How are Graphene Batteries Made?

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Gary graduated from the University of Manchester with a first-class honours degree in Geochemistry and a Masters in Earth Sciences. After working in the Australian mining industry, Gary decided to hang up his geology boots and turn his hand to writing. When he isn't developing topical and informative content, Gary can usually be found playing his beloved guitar, or watching Aston Villa FC snatch defeat from the jaws of victory.

Please use one of the following formats to cite this article in your essay, paper or report:

Thomas, G.P.. (2022, October 26). What Materials are Used in Catalytic Converters?. AZoM. Retrieved on October 02, 2023 from https://www.azom.com/article.aspx?ArticleID=8094.

Thomas, G.P.. "What Materials are Used in Catalytic Converters?". AZoM. 02 October 2023. <https://www.azom.com/article.aspx?ArticleID=8094>.

Thomas, G.P.. "What Materials are Used in Catalytic Converters?". AZoM. https://www.azom.com/article.aspx?ArticleID=8094. (accessed October 02, 2023).

Thomas, G.P.. 2022. What Materials are Used in Catalytic Converters?. AZoM, viewed 02 October 2023, https://www.azom.com/article.aspx?ArticleID=8094.

I need a catalytic converter that is aflame and which I can reroute the gases produced from it's burning, to fuel my vehicle. Like a Worm.

Hi, what are the advantages in use of talc in the composition of automotive catalysts?

yes I no beads are not used any more , but is it true they used 90% more palladium back then because no one new much about palladium back then and cheaper.

The opinions expressed here are the views of the writer and do not necessarily reflect the views and opinions of AZoM.com.

Do you have a review, update or anything you would like to add to this article?

In this interview, AZoM speaks to LECO's Andrew Storey about glow discharge spectrometry and the opportunities offered by LECO's GDS950.

At the Advanced Materials Show 2023, AZoM sat down with Tom Warwick, Director and one of the two Founders of Blue Scientific, to discuss the rapid growth of the business and its ambitions for the future.

Phil Levesque & Charlie Pryor

In this interview, AZoM speaks to Instron's Phil Levesque and Charles Pryor about the importance of mechanical testing for electric vehicle batteries.

The Thermo Scientific™ ARL iSpark™ Plus Series OES Metal Analyzer is the perfect instrument for every process from routine elemental analysis to heavy-duty metals R&D.

Syft Tracer Pharm11 is a bundle solution for high-throughput, 21 CFR Part 11 compliant, automated workflows in pharmaceutical and CDMO applications.

The 6800 Series Multi-Station System offers enhanced throughput with its ability to perform independent tests on up to five separate specimens.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

Ceramic Plate Manufacturer Owned and operated by AZoNetwork, © 2000-2023